Free Design Service

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

Get bulk orders for 30% less than local suppliers, plus free samples.

Power up your brand with Custom Battery Labels that combine durability, precision, and safety. Designed for batteries of all sizes — from AA and AAA to lithium-ion and industrial power cells — these labels are engineered to withstand heat, friction, and constant handling. With specialized adhesives and high-performance materials, your branding and safety information stay clear and secure even under demanding conditions.

To ensure we can accurately produce stickers that meet your expectations, please provide the following information when placing your order:

1. Basic specifications such as shape, rolling finish, quantities, or other requirements.

2. Design Files (Optional, but strongly recommended)

Supported file formats: .ai, .eps, .jpeg, .jpg, .pdf, .png, .psd, .svg, .tif, .tiff

(If you don't have a design file, contact our customer service for free design and modification)

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

All custom stickers and labels are made with advanced printers and premium sticker materials tailored to your needs. The stickers and labels are impressive with sharp details and precise colors.

Stickers and labels are cut to the perfect shape, whether it's simple or complicated. Just send us the requested details, Stickerforgeco can make custom designs fit for your needs.

Stickerforgeco carries out meticulous inspections after the stickers and labels are made. We provide safe and careful packaging to ensure smooth delivery.

Each sticker and label is carefully packaged to ensure safe delivery. They are customized to match your business and branding.

Each order is inspected, packaged, and prepared for fast and express delivery. Stickforgego has established stable business cooperations with mainstream logistic companies to ensure smooth delivery worldwide.

Our laser cutting process ensures a clean, professional finish—designed to reduce peeling and maintain durability across packaging and product applications.

1/8” (0.125”) for smooth, consistent results

1/25” (0.04”), available when your design allows for more precise cuts

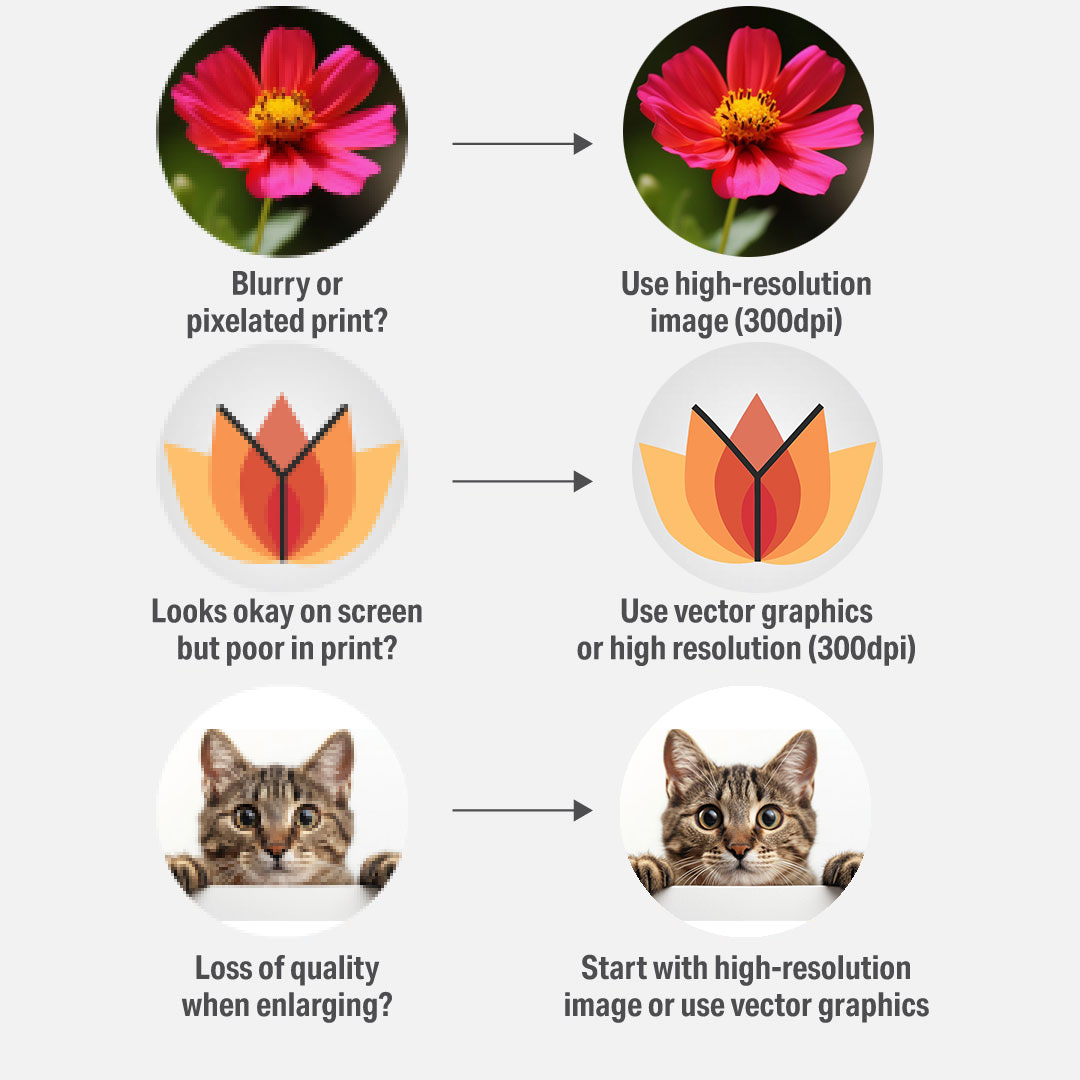

Artwork resolution plays a crucial role in print quality. Here's why 300 DPI is the standard for printing:

High DPI ensures your design looks clean and professional without pixelation.

More pixels result in more precise color representation.

Avoid blurry, distorted prints that may harm your brand's image.

To set up artwork for die-cut stickers, use two layers: one for the artwork and one for the cut path. Ensure your document includes a bleed area ( 0.125 inches), is set to the final size, and has a resolution of at least 300 DPI in CMYK color mode. The cut path should be a distinct, 1-pixel stroke on its own layer, at least 0.25 inches from other cut paths.

Artwork Setup

Size & Layout Guidelines

| Minimum Size: | 0.50” x 0.50” |

| Maximum Size: | 11” x 14” |

| Safety Margin: | Leave at least 1/8” (0.125") of space around the edge of your design to prevent accidental trimming |

| Small Details: | We can print fine elements and fonts as small as 5 pt clearly |

| Wrap-Around Labels: | For containers like tubes or jars, add 1/4” to the length so the label overlaps cleanly |

Design considerations

1.File Format: Submit your design in AI, PDF, or EPS format with all fonts converted to outlines. For digital printing, 300 DPI PNG files with transparent backgrounds are also acceptable.

2.Layers: Use at least two separate layers in your design file:

Artwork Layer: Contains your full design — logo, text, illustrations, and background. Extend all background colors or images to the bleed line.

Cut Path Layer: A vector outline named “Cut Path” that defines the final label shape. Use a 1-pixel stroke for this path.

3.Bleed & Safe Area: Add a 2–3 mm bleed on all sides. Keep essential elements like text, certification marks, and barcodes at least 2 mm inside the cut line to avoid trimming loss.

4.Shape & Fit: Ensure the label fits the curved surface of cylindrical or prismatic batteries. Avoid placing text or critical icons too close to curved edges or seams to prevent distortion.

5.Color Mode: Use CMYK color mode for print accuracy. Avoid RGB or neon tones that may not reproduce accurately on metallic or heat-resistant substrates.

6.Compliance Elements: If required, include warning icons, voltage information, recycling symbols, and certification marks (e.g., CE, UL, RoHS) in accordance with your product's regulatory standards.

7.Material & Adhesive: Specify label type (e.g., polyester, vinyl, or heat-resistant PET) and adhesive strength (permanent or removable). Choose laminated or UV-coated finishes for added protection.

8.Proofing: Request a digital proof or printed sample before full production to verify alignment, color accuracy, and durability under simulated temperature and friction conditions.

Industry-Specific Requirements

If your labels need to meet compliance or packaging standards (e.g., food, cosmetics, supplements), make sure your design includes all required elements—we print what you provide.

Custom Battery Labels

Battery labels must balance precision, durability, and safety. Custom Battery Labels are engineered to withstand extreme temperatures, abrasion, and chemical exposure while maintaining legible, compliant information. Whether for rechargeable batteries, lithium-ion cells, or industrial power units, these labels ensure critical details—such as voltage, warnings, and certifications—stay visible and intact throughout the product’s lifespan.

Custom Battery Labels are used for:

Lithium-ion & Rechargeable Batteries: Display voltage, capacity, and safety icons clearly for both consumers and manufacturers.

Industrial Power Units: Use ultra-durable film or metalized materials that resist heat, oil, and mechanical wear.

Consumer Electronics: Provide sleek branding on small devices like remotes, toys, or cameras.

Automotive & Energy Storage Systems: Include high-temperature adhesives and warning graphics for heavy-duty performance.

Replacement or OEM Products: Match precise sizing and compliance markings for professional presentation.

Battery Label Application Tips:

Apply to clean, oil-free, and dry surfaces to ensure strong adhesion.

Use heat-resistant or UL-recognized materials for high-temperature environments.

Include essential data such as model number, voltage, and certification logos (UL, CE, RoHS, etc.).

Opt for laminated finishes to prevent fading or smearing during handling and storage.

For compact batteries, use small-format high-contrast printing for easy readability.