Free Design Service

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

Get bulk orders for 30% less than local suppliers, plus free samples.

Kiss Cut Stickers are precisely cut through the sticker layer but not the backing paper, allowing each design to peel off easily while keeping the sheet intact. They're perfect for detailed shapes, logos, or collections of multiple stickers on one sheet. This type offers flexibility for both individual use and organized presentation.

To ensure we can accurately produce stickers that meet your expectations, please provide the following information when placing your order:

1. Basic specifications such as shape, rolling finish, quantities, or other requirements.

2. Design Files (Optional, but strongly recommended)

Supported file formats: .ai, .eps, .jpeg, .jpg, .pdf, .png, .psd, .svg, .tif, .tiff

(If you don't have a design file, contact our customer service for free design and modification)

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

All custom stickers and labels are made with advanced printers and premium sticker materials tailored to your needs. The stickers and labels are impressive with sharp details and precise colors.

Stickers and labels are cut to the perfect shape, whether it's simple or complicated. Just send us the requested details, Stickerforgeco can make custom designs fit for your needs.

Stickerforgeco carries out meticulous inspections after the stickers and labels are made. We provide safe and careful packaging to ensure smooth delivery.

Each sticker and label is carefully packaged to ensure safe delivery. They are customized to match your business and branding.

Each order is inspected, packaged, and prepared for fast and express delivery. Stickforgego has established stable business cooperations with mainstream logistic companies to ensure smooth delivery worldwide.

Our laser cutting process ensures a clean, professional finish—designed to reduce peeling and maintain durability across packaging and product applications.

1/8” (0.125”) for smooth, consistent results

1/25” (0.04”), available when your design allows for more precise cuts

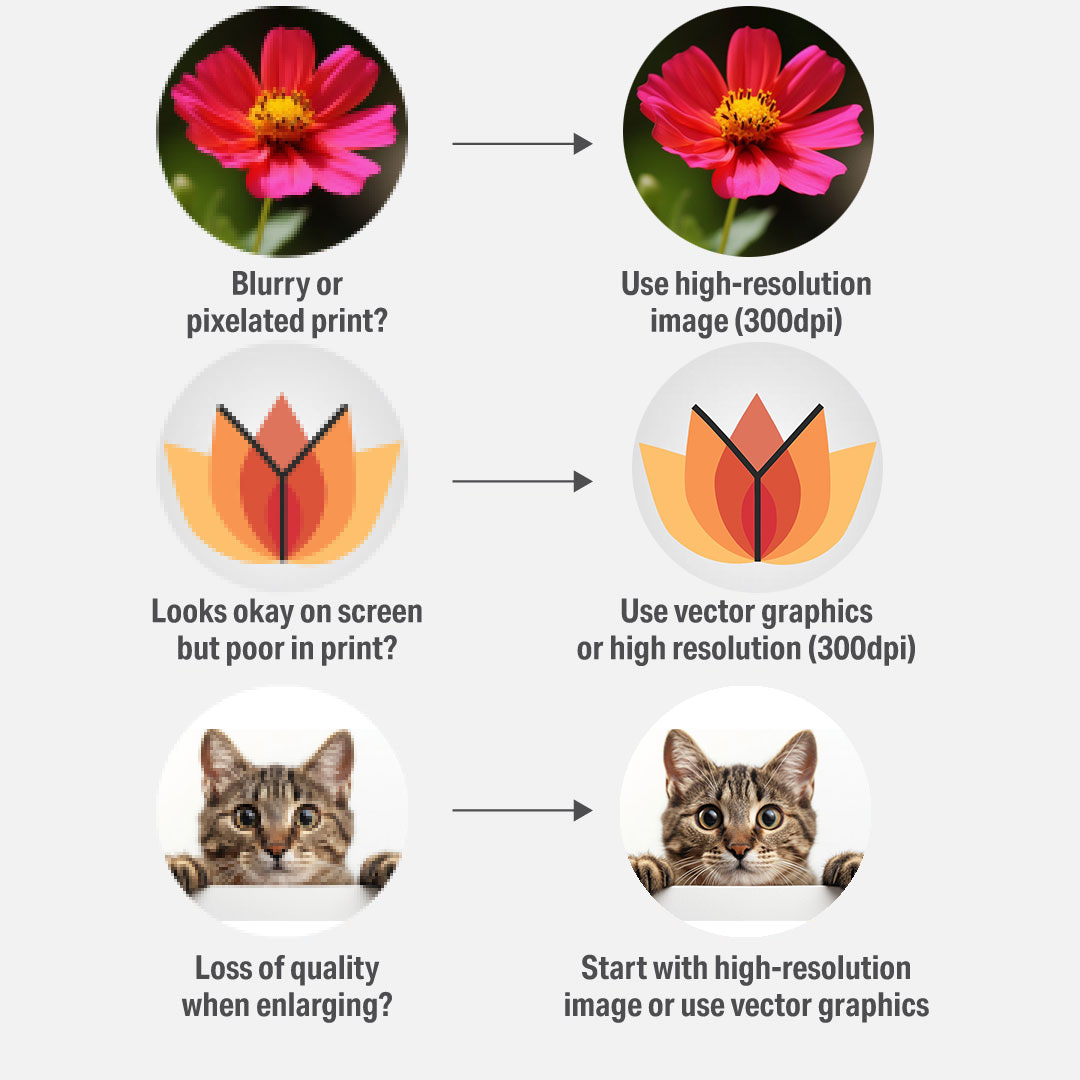

Artwork resolution plays a crucial role in print quality. Here's why 300 DPI is the standard for printing:

High DPI ensures your design looks clean and professional without pixelation.

More pixels result in more precise color representation.

Avoid blurry, distorted prints that may harm your brand's image.

To set up artwork for die-cut stickers, use two layers: one for the artwork and one for the cut path. Ensure your document includes a bleed area ( 0.125 inches), is set to the final size, and has a resolution of at least 300 DPI in CMYK color mode. The cut path should be a distinct, 1-pixel stroke on its own layer, at least 0.25 inches from other cut paths.

Artwork Setup

Size & Layout Guidelines

| Minimum Size: | 0.50” x 0.50” |

| Maximum Size: | 11” x 14” |

| Safety Margin: | Leave at least 1/8” (0.125") of space around the edge of your design to prevent accidental trimming |

| Small Details: | We can print fine elements and fonts as small as 5 pt clearly |

| Wrap-Around Labels: | For containers like tubes or jars, add 1/4” to the length so the label overlaps cleanly |

Design considerations

1.Transparency: Make sure your background is transparent, especially for custom shapes. The kiss cut will follow your sticker’s outer edge, so extend any background colors to the bleed line to avoid white edges after cutting.

2.Layers: Create at least two layers: one for your artwork and one for the cut path.

Artwork Layer: Place your design on the bottom layer. Extend all background colors or images to the bleed line for full coverage.

Cut Path Layer: Create the cut path on a separate layer, often named "Cut Path" or "cut". This should be a vector path outlining the shape of your design.

For kiss cut stickers, you’ll need two vector paths:

Kiss Cut Line – the inner cut that defines the sticker’s shape, cutting only through the vinyl layer (not the backing).

Through Cut Line – the outer cut that defines the shape of the sticker sheet, cutting through both the vinyl and backing paper.

3.Use a 1-Pixel Stroke: Define all cut paths with a 1-pixel stroke (any color works, but 1-pixel is standard). This helps printers clearly distinguish between kiss cuts and through cuts.

4.Label the Cut Paths:

Name your inner path “Kiss Cut.”

Name your outer path “Through Cut.”

This ensures the printer knows which line should only cut the vinyl and which should cut through the entire sheet.

5.Add an Outline: Optionally, add a white or colored border (around 0.125 inches) around your design. This helps your sticker stand out and provides a clean edge once cut.

6.Simplicity: Use bold lines and simple shapes, especially for smaller stickers. Overly intricate designs can be difficult to cut cleanly and may peel unevenly.

7.High Contrast: Designs with high contrast (e.g., dark text on light backgrounds) tend to look sharper and more vibrant after printing.

8.Spacing & Layout:

Maintain at least 0.125 inches (3 mm) of space between multiple kiss-cut designs on one sheet to ensure accurate cutting.

Keep all text and critical design elements within the safe zone.

Industry-Specific Requirements

If your labels need to meet compliance or packaging standards (e.g., food, cosmetics, supplements), make sure your design includes all required elements—we print what you provide.

When you need flexibility and precision in your sticker designs, Kiss Cut Stickers are the perfect choice. Each sticker is carefully cut through the top vinyl layer without slicing the backing paper, allowing for intricate shapes and easy peeling while keeping the full sheet intact. They’re ideal for branding, packaging, or creative sticker collections that require both visual appeal and convenience.

Branding & Logos: Perfect for showcasing detailed logos or designs that stand out with clean, precise edges.

Sticker Sheets: Great for organizing multiple designs on one sheet—ideal for collections or giveaways.

Product Packaging: Add stylish, easy-to-apply stickers to enhance your product’s presentation.

Promotional Items: Offer custom-shaped stickers for marketing events or gifts.

Creative Merch: Artists and designers can sell or share their artwork as collectible sticker sets.

Apply to clean, dry, smooth surfaces for best adhesion.

Peel gently from the edge to avoid damaging fine details.

Store unused sheets flat in a cool, dry place to preserve quality.

Choose from matte, glossy, clear, or holographic finishes for your preferred look.

For outdoor use or extra durability, try Custom Vinyl Stickers.