Free Design Service

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

Get bulk orders for 30% less than local suppliers, plus free samples.

Custom Glossy Labels provide a shiny, vibrant finish, making colors pop. Ideal for food, beverage, and cosmetic packaging, they’re water- and oil-resistant, ensuring durability. Available on rolls for easy application with dispensers. Note: Minimum size for PET backing is 2in x 2in.

To ensure we can accurately produce stickers that meet your expectations, please provide the following information when placing your order:

1. Basic specifications such as shape, rolling finish, quantities, or other requirements.

2. Design Files (Optional, but strongly recommended)

Supported file formats: .ai, .eps, .jpeg, .jpg, .pdf, .png, .psd, .svg, .tif, .tiff

(If you don't have a design file, contact our customer service for free design and modification)

Stickerforgeco provides unique and vibrant colors and sharp designs to make your labels and stickers impressive.

All custom stickers and labels are made with advanced printers and premium sticker materials tailored to your needs. The stickers and labels are impressive with sharp details and precise colors.

Stickers and labels are cut to the perfect shape, whether it's simple or complicated. Just send us the requested details, Stickerforgeco can make custom designs fit for your needs.

Stickerforgeco carries out meticulous inspections after the stickers and labels are made. We provide safe and careful packaging to ensure smooth delivery.

Each sticker and label is carefully packaged to ensure safe delivery. They are customized to match your business and branding.

Each order is inspected, packaged, and prepared for fast and express delivery. Stickforgego has established stable business cooperations with mainstream logistic companies to ensure smooth delivery worldwide.

Our laser cutting process ensures a clean, professional finish—designed to reduce peeling and maintain durability across packaging and product applications.

1/8” (0.125”) for smooth, consistent results

1/25” (0.04”), available when your design allows for more precise cuts

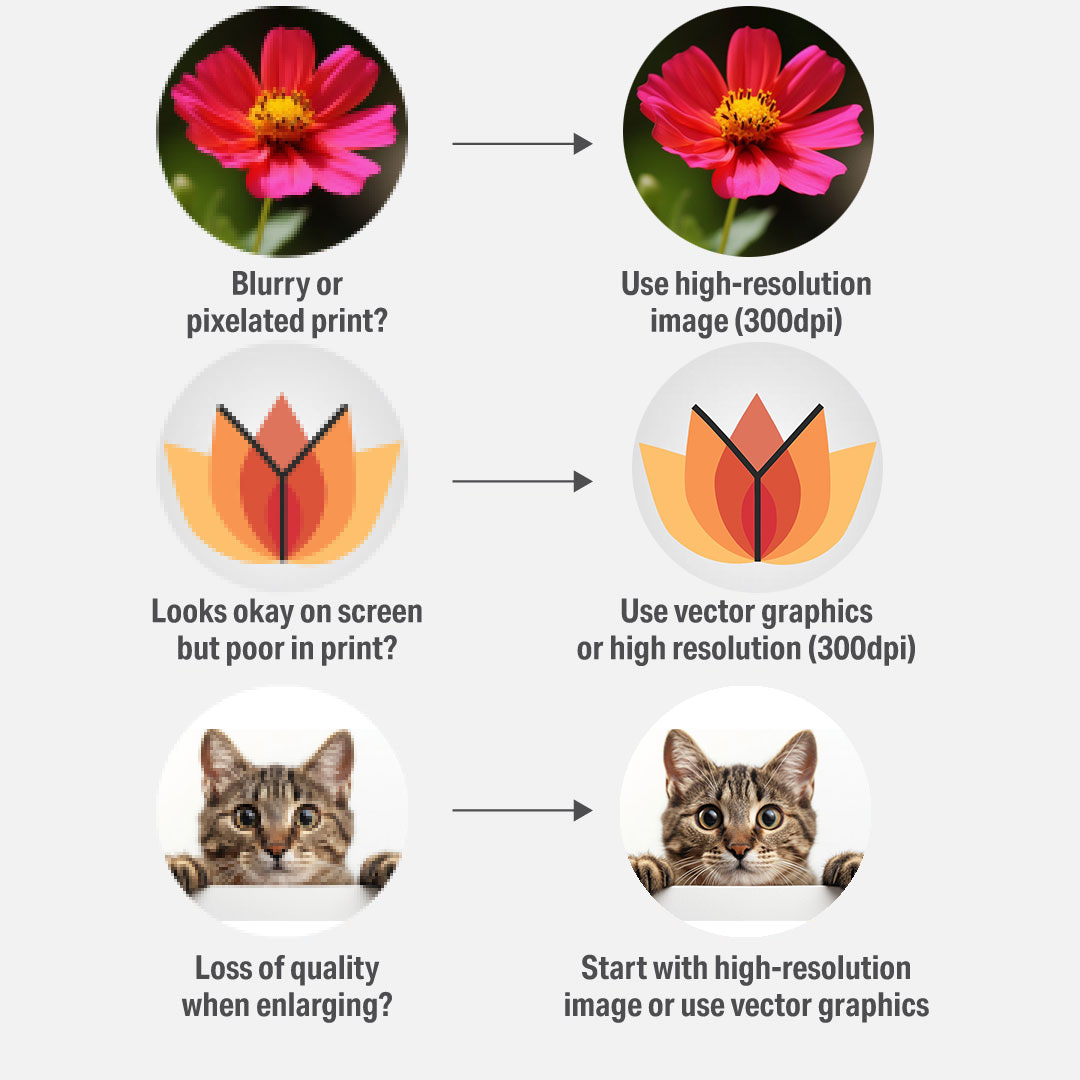

Artwork resolution plays a crucial role in print quality. Here's why 300 DPI is the standard for printing:

High DPI ensures your design looks clean and professional without pixelation.

More pixels result in more precise color representation.

Avoid blurry, distorted prints that may harm your brand's image.

To set up artwork for die-cut stickers, use two layers: one for the artwork and one for the cut path. Ensure your document includes a bleed area ( 0.125 inches), is set to the final size, and has a resolution of at least 300 DPI in CMYK color mode. The cut path should be a distinct, 1-pixel stroke on its own layer, at least 0.25 inches from other cut paths.

Artwork Setup

Size & Layout Guidelines

| Minimum Size: | 0.50” x 0.50” |

| Maximum Size: | 11” x 14” |

| Safety Margin: | Leave at least 1/8” (0.125") of space around the edge of your design to prevent accidental trimming |

| Small Details: | We can print fine elements and fonts as small as 5 pt clearly |

| Wrap-Around Labels: | For containers like tubes or jars, add 1/4” to the length so the label overlaps cleanly |

Design considerations

1.Transparency: Make sure your background is transparent, especially if you’re using a die-cut label. The die-cut will follow the outer edge of your design, so extend any background colors to the bleed line to ensure no white edges after cutting.

2.Layers: Create at least two layers: one for your artwork and one for the cut path.

Artwork Layer: Place your design on the bottom layer. Ensure that any background color or image extends to the bleed line for a seamless, borderless design.

Cut Path Layer: Create the cut path on a separate layer, typically named "Cut Path" or "cut". This should be a vector path outlining the shape of your design.

3.Use a 1-Pixel Stroke: Define the cut with a 1-pixel stroke (any color is fine, but 1-pixel is standard). This makes the cut path clear for the printer to follow.

4.Naming the Layers: Some printers may have specific naming conventions for the cut layer. Always check with your provider to ensure the cut layer is named correctly.

5.Add an Outline: Optionally, you can add a white or colored border (0.125 inches is common) around your design. This will help the design stand out on the glossy material and ensure a clean, defined edge after cutting.

6.Simplicity: High contrast designs (e.g., dark text on a light background or vice versa) will appear more vibrant on glossy labels, making your design pop and ensuring it’s highly visible.

7.High Contrast: Designs with high contrast (e.g., dark text on a light background) tend to stand out more, improving visibility and making your label more eye-catching.

8.Consider the Glossy Effect: The glossy surface can make colors appear brighter and more saturated. Avoid using designs with light or subtle gradients, as the gloss effect can make these elements appear less sharp.

Industry-Specific Requirements

If your labels need to meet compliance or packaging standards (e.g., food, cosmetics, supplements), make sure your design includes all required elements—we print what you provide.

Glossy Labels offer a professional, high-quality look that enhances product packaging, promotions, and brand visibility. Their vibrant colors and durable finish make them an ideal choice for businesses looking to create a polished, eye-catching presentation.

Perfect for food, beverage, and cosmetic packaging, creating a sleek, eye-catching finish.

Use for event giveaways, special edition packaging, or branded marketing materials.

Add a professional touch to packaging, gift boxes, and shipping materials.

Customize labels for conferences, trade shows, or branded merchandise.

Ideal for warehouses, office supplies, and storefronts needing clear, durable labeling.

For best adhesion, apply labels to clean, flat surfaces.

Start from one edge and smooth down to prevent air bubbles.

Take extra caution when applying to curved surfaces (like helmets and water bottles) to prevent wrinkles.

Not food-safe—do not place these labels directly on food or edible items.

Not outdoor durable – For a weather-resistant option, check out our Custom Sticker products.

Perforations cannot be added between labels on the backing.

Not compatible with inkjet or laser printers and cannot be printed on after production.